Why a Class A Die is a Class A Die?

Most of the companies which develop tools or dies claim about manufacturing class-A dies.

But are they genuinely class A dies? There are three categories of dies – A, B & C and there can be two types of class A dies. The differences between them depend on the tooling quality and materials used in manufacturing.

Here, we would try to summarize such differences and understand why a Class A die is a class A die. Let’s dive in.

Class A - Type 1

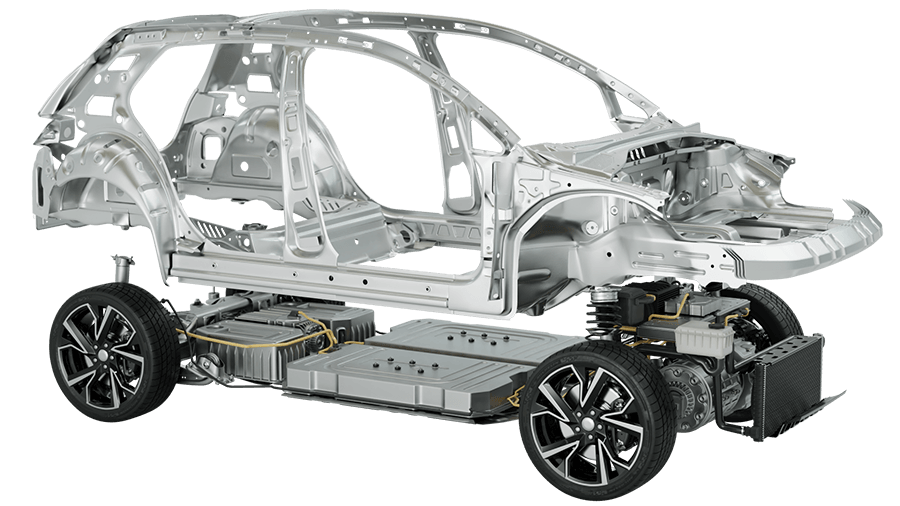

Class A (Type 1) is usually a larger drawing and stretching die used to manufacture parts, which need a smooth, defect free, and aesthetically superior surface. Exterior BIW Parts / Skin Panels such as Body Side Outer, Tail Gate, Fender, Roof, Hood and Outer Doors are few examples of parts which are made with this type of tooling.

The forming dies must have the surface finishes same as or better than the real part surface requirements. As most exterior Body / BIW panels are shaped or contoured, the grinding and finishing process needs a lot of manual work. Thus, the toolmaker should be highly skilled and experienced at tool grinding and finishing. The toolmaker should produce a spot-free (high or low spots) surface using polishing papers, stones, and hand-held grinders as even the smallest defects in the die surface will be visible on the stamped panel.

Class A dies also should be run in a clean environment. Even the smallest pieces of lint from

the press operator’s gloves getting into the die will leave a visible surface defect in the stamped part.

Parts stamped with class A dies are usually coated with a highlight oil to look like a shiny clear coat and then move to a “highlight room,” a room or awning with bright lights, for careful examination from all angles and perspectives to check for the visible skin defect on the stamped panel.

Class A - Type 2

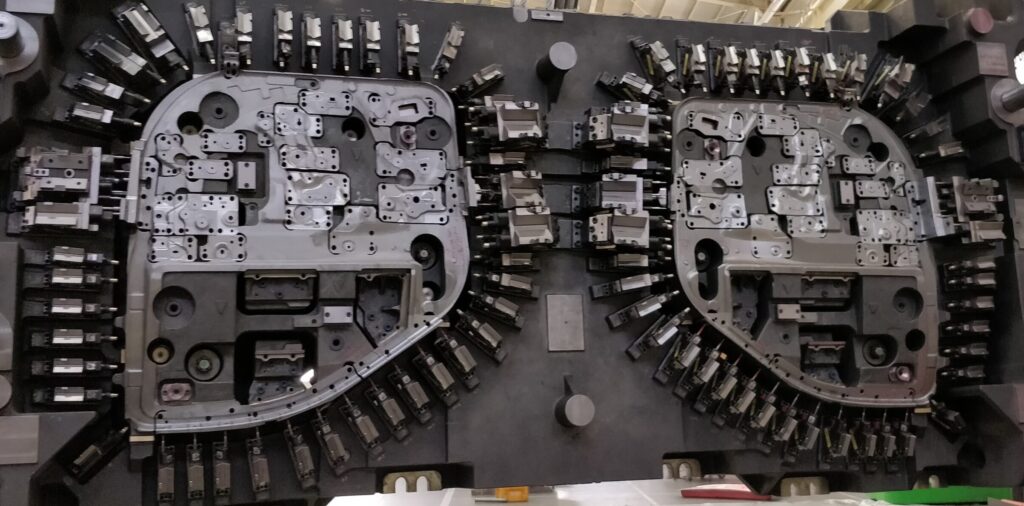

Class A (Type 2) is designed & manufactured with the highest precision and made of the top-quality materials, regardless of the price. These dies can produce very high volumes of parts and be under process for years, like high-speed (500 SPM or greater) progressive dies. Such types of ultraprecision die usually have aluminium die shoes and solid carbide / ceramic functional parts. When tool steel is used, it is of the highest Crucible Particle Metallurgy grade.

Some of these types of progressive dies are running at 1500 SPM and can produce multiple parts per stroke. This shows that the finest material and ultimate level of accuracy is required to manufacture these dies / tools.

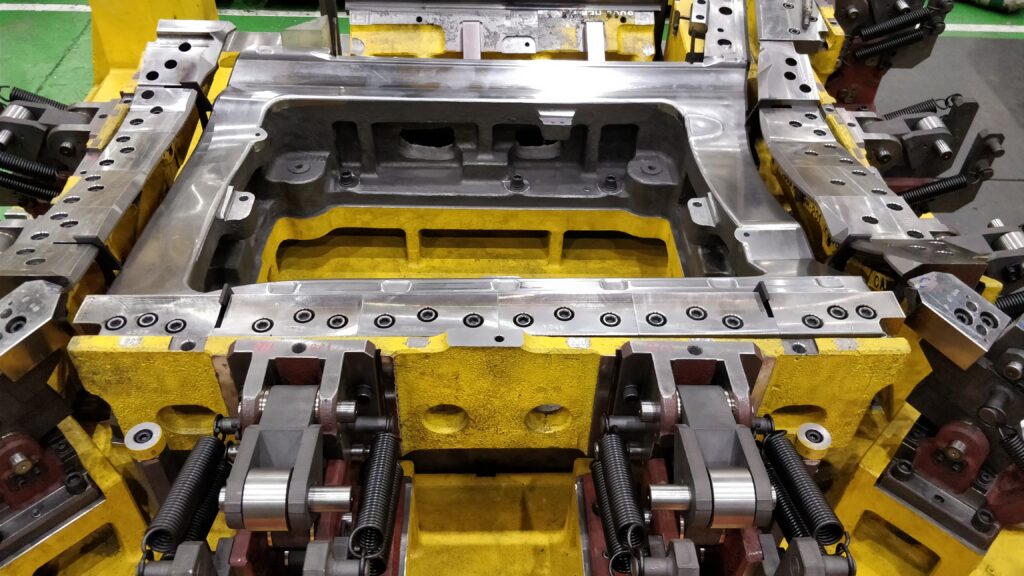

Class B

Most dies used for manufacturing belong to the class B category and are made of typical tool steels such as A2, D2, SKD11 and SLD Magic. Some of them are made of materials, like solid carbide. Such tools are designed, developed and manufactures with materials that tend to stay for the expected production volume required. These type of tools are often used in the automotive industry, as the tooling requires producing parts for a specific car model as long as it’s under production. Class B tools are good enough to perform the task for as long as required.

Class C

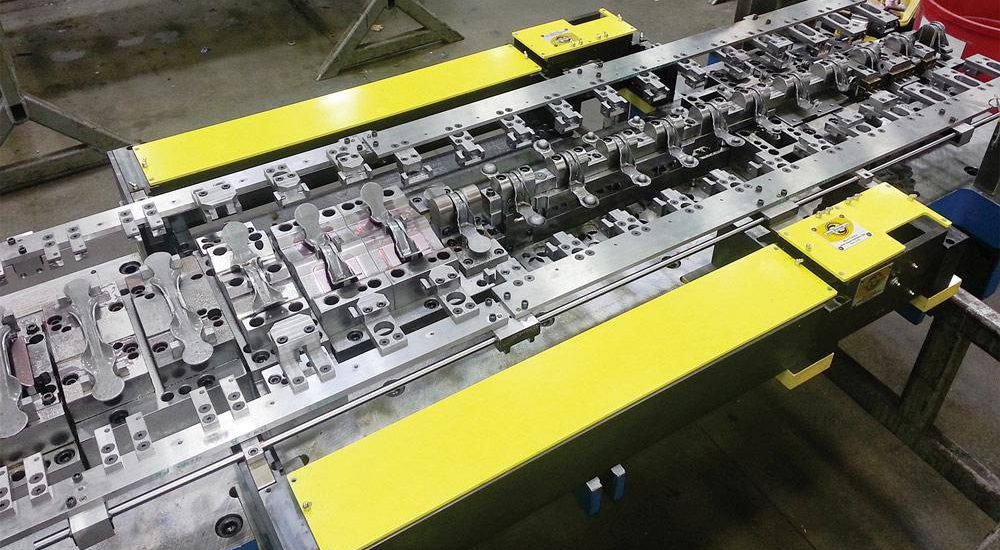

Class C tools are designed, developed, and manufactured with low-cost materials and methods to produce satisfactory parts. They are usually temporary, low volume or prototype tools used to manufacture a few hundred parts. Such tools may be made of affordable tool steel, low-carbon steel, or Kirtsite, which contains zinc and alloying parts of copper, aluminium, and magnesium. As Kirtsite is machinable and recyclable, it’s perfect for low-volume work, such as producing large interior and exterior prototype body / BIW panels.

A toolmaker is the right person for making the decision to classify any tool. However, Stampers must clearly chalk out and explain the requirements to the toolmakers related to the Press Specifications, Volume, Die Life, Accuracy, Aesthetics / Surface Quality requirements and Die Construction Standard. These specifications, information and standards must be followed by the toolmaker to produce the desired tool quality.

Choosing the right Class of Die for a given application is a key to success in a long run!